Carbon nanotube

|

|

Carbon nanotubes are cylindrical carbon molecules with properties that make them potentially useful in extremely small scale electronic and mechanical applications. They exhibit unusual strength and unique electrical properties, and are efficient conductors of heat. Inorganic nanotubes have also been synthesized.

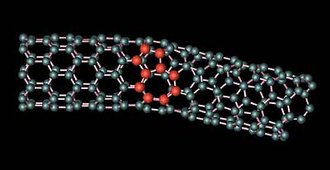

A simple nanotube has a structure similar to a fullerene, but where a fullerene molecule's symmetry is spherical, a nanotube's is cylindrical, with one end typically being capped with half a fullerene molecule. Their name derives from their size; nanotubes are on the order of only a few nanometers wide (on the order of one ten-thousandth the width of a human hair), and their length can be millions of times greater than their width. There are two main types of nanotubes: single-walled nanotubes (SWNT) and multi-walled nanotubes (MWNT).

Nanotubes are composed entirely of sp² bonds, similar to graphite. Stronger than the sp3 bonds found in diamond, this bonding structure provides them with their unique strength. Nanotubes naturally align themselves into "ropes" held together by Van der Waals force. Under high pressure, nanotubes can merge together, trading some sp2 bonds for sp3 bonds, giving great possibility for producing strong, unlimited-length wires through high-pressure nanotube linking. [1] (http://www.ncnr.nist.gov/staff/taner/nanotube/interlink.pdf)

While it has long been known that carbon fibers can be produced with a carbon arc, and patents were issued for the process, it was not until 1991 that Sumio Iijima, a researcher with the NEC Laboratory in Tsukuba, Japan, observed that these fibers were hollow. This feature of nanotubes is of great interest to physicists because it permits experiments in one-dimensional quantum physics.

| Contents |

Single-walled nanotubes

CNTnames.png

Most SWNTs have a diameter of close to 1nm, with a tube length that can be many thousands of times larger. The structure of a SWNT can be conceptualized by wrapping a one-atom-thick layer of graphite (called graphene) into a seamless cylinder. The way the graphene sheet is wrapped is represented by a pair of indices (n,m) called the chiral vector. The integers n and m denote the number of unit vectors along two directions in the honeycomb lattice of graphene. This is often thought of as representing the number of carbon atoms around the circumference of the tube, and the number of atoms down the tube axis. If m=0, the nanotubes are called "zigzag". If n=m, the nanotubes are called "armchair". Otherwise, they are called "chiral".

Properties

The covalent bonding undergone in CNTs means they have very high tensile strengths. In 2000, a SWNT was tested to have a tensile strength of 63GPa (in comparison, high-carbon steel has a tensile strength of approximately 1.2GPa). They also have very high elastic modulus, in the order of 1TPa [2] (http://ipn2.epfl.ch/CHBU/papers/ourpapers/Forro_NT99.pdf).

Under excessive tensile strain, the tubes will undergo plastic deformation, which means the deformation is permanent. This deformation begins at strains of approximately 5% [Qian et al, 2002] and can increase the maximum strain the tube undergoes before fracture by releasing strain energy.

CNTs are much less stronger under compression. Due to their hollow structure, they tend to undergo buckling, when placed under compressive, torsional or bending stress.

Due to the symmetry and unique electronic structure of graphene, the structure of a nanotube strongly affects its electrical properties. For a given (n,m) nanotube, if 2n + m=3q (where q is an integer), then the nanotube is metallic, otherwise the nanotube is a semiconductor. Thus all armchair (n=m) nanotubes are metallic, and nanotubes (5,0), (6,4), (9,1), etc. are semiconducting. An alternative (equivalent) representation of this condition is if (n - m)/3=integer, then the SWNT is metallic. In theory, metallic nanotubes can have an electrical current density more than 1,000 times stronger than metals such as silver and copper.

All nanotubes are expected to be very good thermal conductors along the tube, exhibiting a property known as "ballistic conduction," but good insulators laterally to the tube axis.

As with any material, the existence of defects affect the material properties. Defects can occur in the form of atomic vacancies. High levels of such defects can lower the tensile strength by up to 85% [3] (http://lib.tkk.fi/Diss/2004/isbn9512273799/article5.pdf). Due to the almost one-dimensional structure of CNTs, the tensile strength of the tube is dependent on the weakest segment of it. In a similar manner to a chain, where a defect in a single link will greatly diminish the strength of the entire chain.

In terms of the tube's electrical properties, they too are affected by the presence of defects. A common result is the lowered conductivity through the defected region of the tube. Some defect formation in armchair type tubes (which are metallic) can cause the region sorrounding that defect to become semiconducting.

Synthesis

Techniques have been developed to produce nanotubes in sizeable quantities, but their cost still prohibits any large scale use of them. Fullerenes and carbon nanotubes are not necessarily products of high-tech laboratories, and are also formed in such mundane places as candle flames. However, these naturally occurring varieties are highly irregular in size and quality, and the high degree of uniformity necessary to meet the needs of research and industry is impossible in such an uncontrolled environment. There are several methods employed to make nanotubes, such as arc discharge, laser ablation, and chemical vapor deposition (CVD). In general, the CVD method has shown the most promise in being able to produce larger quantities of nanotube (compared to the other methods) at lower cost. This is usually done by reacting a carbon-containing gas (such as acetylene, ethylene, ethanol, etc.) with a metal catalyst particle (usually cobalt, nickel, or iron) at temperatures above 600°C.

Applications

Nanotubes can be opened and filled with materials such as biological molecules, raising the possibility of applications in biotechnology. They can be used to dissipate heat from tiny computer chips.

The strength and flexibility of carbon nanotubes makes them of potential use in controlling other nanoscale structures, which suggests they will have an important role in nanotechnology engineering. The highest tensile strength an individual SWNT has been tested to be is 63 GPa [4] (http://www.google.com/search?hl=en&ie=ISO-8859-1&q=nanotubes+%22tensile+strength%22+%2263+GPa%22&btnG=Google+Search). In Earth's upper atmosphere, atomic oxygen erodes the carbon nanotubes, but other applications of carbon nanotubes rarely need the surface to be protected. Though it is debatable if nanotube materials can ever be made with a tensile strength approaching that of individual tubes, composites may still yield incredible strengths potentially sufficient to allow the building of such things as space elevators, artificial muscles, ultrahigh-speed flywheels, and more. MIT is working on combat jackets utilizing carbon nanotubes for ultrastrong fibers and for monitoring its wearer's condition.

Carbon nanotubes have already been used as composite fibers in polymers and concrete to improve the mechanical, thermal and electrical properties of the bulk product. Researcher Deepak Srivastava and others have found that adding them to polyethylene increases the polymer's elastic modulus by 30%. In concrete, they increase the tensile strength, and halt crack propagation.

Conductive carbon nanotubes have been used for several years in brushes for commercial electric motors. They replace traditional carbon black, which is mostly impure spherical carbon fullerenes. The nanotubes improve electrical and thermal conductivity because they stretch through the plastic matrix of the brush. This permits the carbon filler to be reduced from 30% down to 3..6%, so that more matrix is present in the brush. Nanotube composite motor brushs are better-lubricated (from the matrix), cooler-running (both from better lubrication and superior thermal conductivity), less brittle (more matrix, and fiber reinforcement), stronger and more accurately moldable (more matrix). Since brushes are a critical failure point in electric motors, and also don't need much material, they became economical before almost any other application.

Carbon nanotubes additionally can also be used to produce nanowires of other chemicals, such as gold or zinc oxide. These nanowires in turn can be used to cast nanotubes of other chemicals, such as gallium nitride. These can have very different properties from CNTs - for example, gallium nitride nanotubes are hydrophilic, while CNTs are hydrophobic, giving them possible uses in organic chemistry that CNTs could not be used for.

One use for nanotubes that has already been developed is as extremely fine electron guns, which could be used as miniature cathode ray tubes in thin high-brightness low-energy low-weight displays. This type of display would consist of a group of many tiny CRTs, each providing the electrons to hit the phosphor of one pixel, instead of having one giant CRT whose electrons are aimed using electric and magnetic fields. These displays are known as Field Emission Displays (FEDs). A nanotube formed by joining nanotubes of two different diameters end to end can act as a diode, suggesting the possibility of constructing electronic computer circuits entirely out of nanotubes. Nanotubes have been shown to be superconducting at low temperatures.

Nanotubes are the critical material that enables contruction of Space Elevators from Earth to geosynchronous orbit. No other known material has the needed strength.

Current progress

One application for nanotubes that is currently being researched is high tensile strength fibers. Two methods are currently being tested for the manufacture of such fibers. A French team has developed a liquid spun system that involves pulling a fiber of nanotubes from a bath which yields a product that is approximately 60% nanotubes. The other method, which is simpler but produces weaker fibers uses traditional melt-drawn polymer fiber techniques with nanotubes mixed in the polymer. After drawing, the fibers can have the polymer burned out of them to make them purely nanotube or they can be left as they are.

Ray Baughman's group from the NanoTech Institute at University of Texas at Dallas produced the current toughest material known in mid-2003 by spinning fibers of single wall carbon nanotubes with polyvinyl alcohol. Beating the previous contender, spider silk, by a factor of four, the fibers require 600J/g to break. In comparison, the bullet-resistant fiber Kevlar is 27-33J/g.

In 2004 Alan Windle's group of scientists at the Cambridge-MIT Institute developed a way to make carbon nanotube fiber continuously at the speed of several centimetres per second just as nanotubes are produced. One thread of carbon nanotubes was more than 100 metres long. The resulting fibers are electrically conductive and as strong as ordinary textile threads. [5] (http://news.bbc.co.uk/2/hi/science/nature/3872931.stm) [6] (http://www.newscientist.com/news/news.jsp?id=ns99994769)

High purity (80%) nanotubes with metallic properties can be extracted with electrophoretic techniques. [7] (http://physicsweb.org/article/news/7/6/19/1)

In April of 2001, IBM announced it had developed a technique for automatically developing pure semiconductor surfaces from nanotubes.

On September 19, 2003, NEC Corporation, Japan, announced (http://www.nec.co.jp/press/en/0309/1901.html) stable fabrication technology of carbon nanotube transistors.

In June 2004 scientists from China's Tsinghua University and Louisiana State University demonstrated the use of nanotubes in incandescent lamps, replacing a tungsten filament in a lightbulb with a carbon nanotube one.

Nanomechanical computer storage devices using nanotubes are currently in the prototype stages. Both high speed non-volatile memory which can be used to replace nearly all solid state memory in computers today, and high density storage that may replace hard drives, are being developed. Major limiting factors in the development of nanotubes include their cost and difficulties in orienting the nanotubes, which tend to tangle because of their length.

As of 2003, nanotubes cost from 20 euro per gram to 1000 euro per gram, depending on purity, composition (single-wall, double-wall, multi-wall) and other characteristics.

Japanese manufacturer Mitsui & Company has announced plans to build the world's first mass production facility for Carbon Nanotubes. Using technology developed at their research facility, they expect to reduce the selling price of Nanotubes to less than 100 yen per gram.

In 2004, Nature published a photo (http://healthspace.ca/Websites/Staff/AJP/DanglingParticiple.nsf/d6plinks/APRE-6B5UMS) of an individual 4 cm long single-wall nanotube (SWNT).

Carbon nanotubes in electrical circuits

Carbon nanotubes have many properties—from their unique dimensions to an unusual current conduction mechanism—that make them ideal components of electrical circuits, and it is exciting to envision, or even to implement, novel transistors, MEMS devices, interconnects, and other circuit elements.

The major hurdles that must be jumped for carbon nanotubes to find prominent places in circuits relate to fabrication difficulties. The carbon nanotube production processes are very different from the traditional IC fabrication process. The IC fabrication process is somewhat like sculpture—films are deposited onto a wafer and pattern-etched away. Carbon nanotubes are fundamentally different from films; they are like atomic-level spaghetti (and every bit as sticky).

Today, there is no reliable way to arrange carbon nanotubes into a circuit. Researchers sometimes resort to manipulating nanotubes one-by-one with the tip of an atomic force microscope in a painstaking, time-consuming process. Perhaps the best hope is that carbon nanotubes can be grown through a chemical vapor deposition process from patterned catalyst material on a wafer, which serve as growth sites and allow designers to position one end of the nanotube. During the deposition process, an electric field can be applied to direct the growth of the nanotubes, which tend to grow along the field lines from negative to positive polarity. Another way for the self assembly of the carbon nanotube transistors consist in using chemical or biological techniques to place the nanotubes from solution to determinate place on a substrate.

Even if nanotubes could be precisely positioned, there remains the problem that, to this date, engineers have been unable to control the types of nanotubes—metallic, semiconducting, single-walled, multi-walled—produced. This is a problem that chemical engineers must solve if nanotubes are to find a place in commercial circuits.

External links

- Commercial source of carbon nanotubes (http://www.ntp.com.cn) NTP-nanotube manufacturer in China

- Ahwahnee Technology (http://www.ahwahneetech.com) Silicon Valley carbon nanotube developer

- The Nanotube site (http://www.pa.msu.edu/cmp/csc/NTSite/nanopage.html)

- The wonderous World of Carbon Nanotubes (http://students.chem.tue.nl/ifp03/Wondrous%20World%20of%20Carbon%20Nanotubes_Final.pdf) (Good introduction to nanotubes)

- Jamieson V. "Open secret" New Scientist (http://www.newscientist.com/hottopics/tech/article.jsp?id=23864900&sub=Nanotechnology)

- Nantero (http://www.nantero.com/mission.html) (developers of nanotube based non-volatile memory)

- University of Cambridge, UK, Research group website (http://www.cheng.cam.ac.uk/research/groups/biosci/hg_research.html) (Affordable methods for making carbon nanotubes and using them for gene delivery)

- University of Texas at Dallas NanoTech Institute (http://www.utdallas.edu/dept/chemistry/nanotech)

- NanoDiamond (http://nanoDiamond.info/) (nanotubes arranged in a diamond formation yielding a very high strength-to-weight ratio material)

- Carbon Nanotube & Fullerene Models - Vincent Herr, Houston, TX (http://www.vincentherr.com/cf/)

- Science News - Nanotube Super Fibers (http://www.sciencenews.org/articles/20030614/fob3.asp)

- Nanotube production in 2003 (http://nanotech-now.com/nanotube-survey-april2003.htm)

- Columbia University Nanoscale Science and Engineering Center presents "Our Energy Challege" September 23, 2003 (http://smalley.rice.edu/)

- Review of Non-Oil and Gas Research Activities in the Houston-Galveston-Gulf Coast Area (http://www.house.gov/science/hearings/energy03/dec04/smalley.htm)

- commercial sources (http://www.helixmaterial.com/product.html)

- Carbon Designs, Inc. http://NanotubeComposites.com/ (http://NanotubeComposites.com/)

- "For pure nanotubes add water" article by Eric Smalley 2004-12 (http://trnmag.com/Stories/2004/120104/For_pure_nanotubes_add_water_120104.html) "stands of single-wall carbon nanotubes as tall as 2.5 millimeters and 99.98 percent pure. Individual nanotubes range from one to three nanometers in diameter."de:Kohlenstoffnanoröhre

es:Nanotubo fr:Nanotube ja:カーボンナノチューブ pl:Nanorurka pt:Nanotubo de Carbono ru:Углеродные нанотрубки fi:Nanoputki