Continuously variable transmission

|

|

Template:Transmission types A continuously variable transmission (CVT) is a type of automatic transmission that can change the "gear ratio" (gears are not generally involved) to any arbitrary setting within the limits. The CVT is not constrained to a small number of gear ratios, such as the 4 to 6 forward ratios in typical automotive transmissions. CVT control computers often emulate the traditional abrupt gear changes, especially at low speeds, because most drivers expect the sudden jerks and will reject a perfectly smooth transmission as lacking in apparent power.

| Contents |

Pulley-based CVT

This type of CVT uses pulleys, typically connected by a metal-covered rubber belt. A chain may also be used. A large pulley connected to a smaller pulley with a belt or chain will operate in the same manner as a large gear meshing with a smaller gear. Typical CVTs have pulleys formed as pairs of opposing cones. Moving the cones in and out has the effect of changing the pulley diameter, since the belt or chain must take a large-diameter path when the conical pulley halves are close together.

In the case of a chain the links bear on the pulleys via tapered sides on the links. Some such transmissions have been designed to transmit the forces between pulleys using compressive (pushing) rather than traction (pulling) forces. Some chain driven transmissions have used a special lubricant which under extreme pressure undergoes a phase change to a glassy solid.

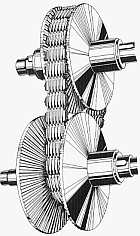

Roller-based CVT

Consider two almost-conical parts, point to point, with the sides dished in such that the two parts could fill the central hole of a torus. One part is the input, and the other part is the output (they do not quite touch). Power is transferred from one side to the other by one or more rollers. When the roller's axis is perpendicular to the axis of the almost-conical parts, it contacts the almost-conical parts at same-diameter locations and thus gives a 1:1 gear ratio. The roller can be moved along the axis of the almost-conical parts, changing angle as needed to maintain contact. This will cause the roller to contact the almost-conical parts at varying and distinct diameters, giving a gear ratio of something other than 1:1.

Hydrostatic CVT

Some continuously variable transmissions instead use a variable displacement pump and a hydraulic motor to transmit power. These types can generally transmit more torque, but they are very expensive to buy and maintain. However, they have the advantage that the hydraulic motor can be mounted directly to the wheel hub, allowing a more flexible suspension system and eliminating efficiency losses from friction in the drive shaft and differential components. This type of transmission has been effectively applied to expensive versions of light duty ridden lawn mowers and garden tractors.

Advantages and drawbacks

CVTs have much smoother operation than hydraulic automatic transmissions, are simpler to build and repair and provide better fuel economy by avoiding torque converter losses. Their torque handling capability is limited by the friction and strength of the belt or chain, and so CVTs have typically been limited to low powered cars and other light duty applications.

CVTs can smoothly compensate for changing vehicle speeds, allowing the engine speed to remain at its level of peak efficiency. This improves both fuel economy and exhaust emissions, but some car drivers are bothered by the resulting lack of feedback about vehicle speed provided by engine sound. One magazine described it as sounding like driving a powerboat when accelerating. The satisfying jerk of a non-CVT transmission can be emulated by CVT control software though, eliminating this marketing problem.

History

According to TOROTRAK, the first patent for a toroidal CVT was filed at the end of the 19th century [1] (http://www.torotrak.com/history.html).

The first workable CVT, called VARIOMATIC, was designed and built by dutch Hub van Doorne, co-founder of DAF, in the late 1950s, specifically to produce an automatic transmission for a small, affordable car. The first DAF car using van Doorne's CVT was produced in 1958. Van Doorne's patents were later sold to Volvo along with DAF's car business.

In the 1980s and 1990s, the Subaru Justy was offered with a CVT. While the Justy saw only limited success, Subaru continues to use CVT in its keicars to this day, while also supplying it to other manufacturers.

Nissan first introduced CVT in the 1992 Nissan March with a unit sourced from Subaru. In the late 1990s, Nissan designed its own CVT that allowed for higher torque, and includes a torque converter. This gearbox was used in a number of Japanese market models. Nissan is also the only car maker to bring roller-based CVT to the market in recent years. Their toroidal CVT, named the X-troid, was available in the Japanese market Y34 Nissan Gloria and V35 Skyline GT-8. However, the gearbox was not carried over when the Cedric/Gloria was replaced by the Nissan Fuga in 2004.

After studying pulley-based CVT for years, Honda also introduced their own version on the 1995 Honda Civic. Dubbed Honda Multi Matic, this CVT gearbox accepted higher torque than traditional pulley CVTs, and also includes a torque converter for "creep" action.

General Motors designed a CVT for use in small cars, which was first offered in 2002. After just three years, however, this transmission will be phased out in favor of conventional planetary automatic transmissions.

Audi has, since 2000, offered a chain-type CVT as an option on some of its larger-engined models, for example the A4 3.0L V6.

The 2005 Ford Freestyle and Five-hundred uses a new belt-driven CVT.

CVT transmissions have been refined over the years and are much improved from their origins.

Examples

Many small tractors for home and garden use have simple CVTs, as do most snowmobiles. Almost all motor scooters today are equipped with CVT.

Possibly the largest vehicle currently sold with a CVT is the Nissan Murano, a mid-size sport utility vehicle with a 3.5L V6 engine. The CVT is also available for Audi, Fiat, Honda, Mercedes-Benz and Mini Cooper cars.

Some combines have CVT. The machinery of a combine is adjusted to operate best at a particular engine speed. The CVT allows the forward speed of the combine to be adjusted independently of the machine speed. This allows the operator to slow down and speed up as needed to accommodate variations in thickness of the crop.

Automobiles equipped with CVT

- Audi A4 2.0/1.8T/2.4/3.0/2.5 TDI

- Audi A6 2.0/1.8T/2.4/3.0/2.5 TDI

- Fiat Punto 1.2

- Ford Escape Hybrid 2.3 4cyl

- Ford Focus C-MAX 1.6 TDCi 110ps

- Honda Civic Hybrid 1.3 4cyl

- Honda HR-V 1.6

- Honda Insight 1.0 3cyl

- Mini

- Nissan Micra 1.0/1.3

- Nissan Murano 3.5

- Nissan Primera 2.0

- Nissan Serena 2.0

- Opel Vectra 1.8

- Saturn VUE 2.2/3.5

- Toyota Prius 1.5 4cyl

External links

- eCars.com.au page about CVT (http://www.ebroadcast.com.au/ecars/A.hints/CVT.html)

- AutoZine Technical School - CVT (http://www.autozine.org/technical_school/gearbox/tech_gear_cvt.htm)