Industrial Revolution

|

|

The dating of the Industrial Revolution is not exact, but it covers roughly 1760-1830, in effect, the reigns of George III, The Regency, and part of William IV. There was no cut-off point for it merged into the Second Industrial Revolution from about 1850, when technological and economic progress gained momentum with the development of steam-powered ships, and railways, and later in the nineteenth century the growth of the internal combustion engine and the development of electrical power generation.

The effects spread throughout Western Europe and North America, eventually affecting the rest of the world. The impact of this change on society was enormous and is often compared to the Neolithic revolution, when mankind developed agriculture and gave up its nomadic lifestyle.

The term industrial revolution was introduced by Friedrich Engels and Louis-Auguste Blanqui in the second half of the 19th century.

| Contents |

Causes

The causes of the Industrial Revolution were complex and remain a topic for debate, with some historians seeing the Revolution as an outgrowth of social and institutional changes wrought by the end of feudalism in Great Britain after the English Civil War in the 17th century. The Inclosure movement and the British Agricultural Revolution made food production more

The presence of a large domestic market should also be considered an important catalyst of the Industrial Revolution, particularly explaining why it occurred in Britain. In other nations, such as France, markets were split up by local regions, which often imposed tolls and tariffs on goods traded among them.

From about 1100, the population of Europe rose, which is because there was recovery from the disorder in the early medieval times, and there was development in agriculture and trade. The population in Europe grew quickly from 1700 onwards, because there was a scientific and technological improvement, growth of supply of food because of the improvement in agriculture, and the people in Europe became wealthy because of overseas trade. The number of deaths decreased and the number of births increased. As there were more people, they needed more goods. Machines were then invented to produce more goods to meet the needs of the people.

From 1430, people in Europe discovered sea routes to Asia and America. England made the greatest gain from overseas trade. The middle class in England became wealthy from overseas trade. Their social position grew greatly. The manufacturers were ready to invest in the making of machines and setting up factories. The large overseas market also encouraged industrialists to produce more products quicker and of better quality, so they invested in the production of machines in England.

As the banking system developed, the banks lent money to the industrialists from the money of the merchants and manufacturers. The industrialists then used the money for industrial development, which led to the Industrial Revolution.

The rapid growth of science and technology since the 17th century greatly helped in the rise of the Industrial Revolution. It was the reason for the growth of population, the basis for the invention of machines and the Agricultural Revolution.

In Britain, the influence of the merchants and manufacturers was considerable as there was privilege and monopoly. The abundant supply of coal and iron ore made the making of machines easier. Europe was also politically stable, so people didn’t worry about law and order, and set their minds into manufacturing. People earned a lot of money form the slave trade, so there was capital for the industrialists.

Agricultural Revolution is also an important factor for the Industrial Revolution. Crop rotation and Enclosure Movement increased the amount of food produced and supplied a sufficient amount of food for the workers working in the cities. Selective breeding produced food with better quality. The Enclosure Movement also made poor farmers go to the town to work as they had no more land to farm on.

Innovations

The invention of the steam engine was the most important innovation for the industrial revolution. Others followed: the spinning jenny revolutionized textile manufacturing and new metal working technologies were introduced. Another important innovation was the organization of human labor in factories.

Transmission of innovation

Knowledge of new innovation was spread by several means. Workers who were trained in the technique might move to another employer, or might be poached. A common method was for someone to make a study tour, gathering information where he could. Today this is called industrial espionage, with modern concepts of automatic illegality.

During the whole of the Industrial Revolution and for the century before, all European countries and America engaged in this manner of study-touring; some nations, like Sweden and France, trained civil servants or technicians to undertake it as a matter of state policy. In other countries, notably Britain and America, this practice was carried out by individual manufacturers anxious to improve their own methods. Study tours were common then, as was the keeping of travel diaries; writings made by industrialists and technicians of the period are an incomparable source of information about their methods.

Another means for the spread of innovation was by the network of informal philosophical societies like the Lunar Society of Birmingham, in which members met to discuss science and often its application to manufacturing. Some of these societies published volumes of proceedings and transactions, and the London-based Society for the encouragement of Arts, Manufactures and Commerce or, more commonly, Society of Arts published an illustrated volume of new inventions, as well as papers about them in its annual Transactions.

There were publications describing the technology. Encyclopaedias such as Harris's Lexicon technicum (1704) and Dr Abraham Rees's Cyclopaedia (1802-1819) contain much of value. Rees's Cyclopaedia contains an enormous amount of information about the science and technology of the first half of the Industrial Revolution, very well illustrated by fine engravings. Foreign printed sources such as the Descriptions des Arts et Metiers and Diderot's Encyclopedie explained foreign methods with finely engraved plates.

Periodical publications about manufacturing and technology began to appear in the last decade of the 18th century, and a number regularly included notice of the latest patents. Foreign periodicals such as the Annales des Mines published accounts of travels made by French engineers who observed British methods on study tours.

Factories

Industrialization also led to the creation of the factory. John Lombe's water-powered silk mill at Derby was operational by 1721. In 1746 an integrated brass mill was working at Warmley near Bristol. Raw material went in at one end, was smelted into brass, and was turned into pans, pins, wire, and other goods. Housing was provided for workers on-site.

Josiah Wedgwood and Matthew Boulton were other prominent early industrialists.

The factory system was largely responsible for the rise of the modern city, as workers migrated into the cities in search of employment in the factories. For much of the 19th century, production was done in small mills, which were typically powered by water and built to serve local needs.

The transition to industrialization was not wholly smooth. For example, a group of English workers known as Luddites formed to protest against industrialization and sometimes sabotaged factories.

One of the earliest reformers of factory conditions was Robert Owen.

Machine tools

The Industrial Revolution could not have developed without machine tools, for they enabled manufacturing machines to be made. They have their origins in the tools developed in the 18th century by makers of clocks and watches, and scientific instrument makers to enable them to batch-produce small mechanisms. The mechanical parts of early textile machines were sometimes called 'clock work' due to the metal spindles and gears they incorporated. The manufacture of textile machines drew craftsmen from these trades and is the origin of the modern engineering industry. Machine makers early developed special purpose machines for making parts.Machines were built by various craftsmen. Carpenters for making the wooden framing, and smith and the turner for the metal parts. Because of the difficulty of manipulating metal, and the lack of machine tools, metal was reduced to a minimum. Wood framing had the disadvantage of changing dimensions with temperature and humidity, and the various joints used tended to rack (work loose) over time. As the Industrial Revolution progressed, machines with metal frames became more common, but required machine tools to make them economically. Before the advent of machine tools metal was worked manually using the basic hand tools of hammers, files, scrapers, saws and chisels. Small metal parts were readily made by this means, but for large machine parts, such as castings for a lathe bed, where components had to slide together, the production of flat surfaces by means of the hammer and chisel followed by filing, scraping and perhaps grinding with emery paste, was very laborious and costly.

Apart from workshop lathes used by craftsmen, the first large machine tool was the cylinder boring machine, used for boring the large-diamater cylinders on early steam engines. They were to be found at all steam-engine manufacturers. The planing machine, the slotting machine and the shaping machine were developed in the first decades of the 19th century. Although the milling machine was invented at this time, it was not developed as a serious workshop tool until during the Second Industrial Revolutuion.

Military production had a hand in their development. Henry Maudslay, who trained a school of machine-tool makers early in the 19th century, was employed at the Royal Arsenal, Woolwich, as a lad where he would have seen the large horse-driven wooden machines for cannon boring made and worked by the Verbruggans. He later worked for Joseph Bramah on the production of metal locks, and soon after he began working on his own account was engaged to build the machinery for making ships' pulley blocks for the Royal Navy in the Portsmouth Block Mills. These were all metal, and the first machines for mass production and making components with a degree of interchangeability. The lessons Maudslay learned about the need for stability and precision he adapted to the development of machine tools, and in his workshops he trained a generation of men to build on his work, such as Richard Roberts, Joseph Clement and Joseph Whitworth.

Maudslay made his name for his lathes and precision measurement. James Fox of Derby had a healthy export trade in machine tools for the first third of the century, as did Matthew Murray of Leeds. Roberts made his name as a maker of high-quality machine tools, and as a pioneer of the use of jigs and gauges for precision workshop measurement.

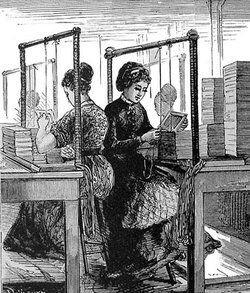

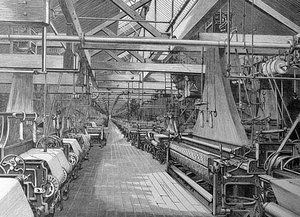

Textile manufacture

In the early 18th century, British textile manufacture was based on wool which was processed by individual artisans, doing the spinning and weaving on their own premises. This system is called a cottage industry. Flax and cotton were also used for fine materials, but the processing was difficult because of the pre-processing needed, and thus goods in these materials made only a small proportion of the output.

Use of the spinning wheel and hand loom restricted the production capacity of the industry, but a number of incremental advances increased productivity to the extent that manufactured cotton goods became the dominant British export by the early decades of the 19th century. India was displaced as the premier supplier of cotton goods.

Step by step, individual inventors increased the efficiency of the individual steps of spinning (carding, twisting and spinning, and subsequently rolling) so that the supply of yarn fed a weaving industry that itself was advancing with improvements to shuttlewith the effect that these new machines were seen as a threat to employment, and early innovators were attacked and their inventions wrecked. The inventors often failed to exploit their inventions, and fell on hard times.

To capitalize upon these advances it took a class of entrepreneurs, of which the most famous is Richard Arkwright. He is credited with a list of inventions, but these were actually developed by people such as Thomas Highs and John Kay; Arkwright nurtured the inventors, patented the ideas, financed the initiatives, and protected the machines. He created the cotton mill which brought the production processes together in a factory, and he developed the use of power – first horse power, then water power and finally steam power – which made cotton manufacture a mechanised industry.

Mining

Coal mining in Britain is of great age. Before the steam engine, pits were often shallow bell pits, following a seam of coal along the surface and being abandoned as the coal was extracted. In other cases, if the geology was favourable, the coal was mined by means of an adit driven into the side of a hill. Shaft mining was done in some areas, but the limiting factor was the problem of removing water. It could be done by hauling buckets of water up the shaft by means of a horse gin, or it could be drained by an adit leading to a stream or ditch at lower level where it could flow away by gravity. A number of historic mining areas of Britain, such as the Kingswood coalfield near Bristol, still have adits running to this day, as of 2005, almost a century after the industry ceased. The introduction of the steam engine enabled shafts to be made deeper, hence increasing output.Metallurgy

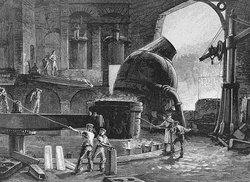

Principal suppliers of high-quality iron goods were Sweden and Russia, with Russia being able to command increasingly high prices as Britain's need grew.

To fuel the iron smelting process, people moved from wood to coal and coke. Production of pig iron, cast iron and wrought iron improved through the exchange of ideas (although this was by no means a fast process), with the most well-known name being Abraham Darby. The first Abraham Darby made great strides with using coke to fuel his blast furnaces at Coalbrookdale 1709, although this was principally due to the nature of the coke he was using, and the scientific reasons for the improvement were only discovered later. His family followed in his footsteps, and iron became a major construction material.

Other improvements followed, with Benjamin Huntsman developing a crucible steel technique in the 1740s, and Henry Cort's puddling furnace enabling large-scale production of wrought iron to take place.

The reliance on overseas supplies was diminished, and improvements in machine tools and the use of iron and steel in the development of the railways further boosted the industrial growth of Great Britain.

Steam power

The stationary steam engine had great influence on the progress of the Industrial Revolution, but for all of it many industries still relied on wind and water power as well as horse and man-power for driving small machines.

The steam engine was first used for draining mines or for driving mills by pumping water back to a reservoir that had passed through a water wheel. James Watt's invention of rotary motion in the 1780s enabled a steam engine to drive a factory or mill directly.

Until about 1800, the most common pattern of steam engine was the beam engine, which was built within a stone or brick engine-house but after then various patterns of portable (ie readily removable engines, not on wheels) were developed, such as the table engine. The development of machine tools such as the planing and shaping machine enabled all the metal parts of the engines to be easily and accurately cut. Engines could be made in varying sizes and patterns to suit various requirements, such as for locomotives and steam boats.

Transportation

At the beginning of the Industrial Revolution, inland transport was by navigable rivers and roads, with coastwise vessels employed to move heavy goods by sea. Railways or waggon ways were used for conveying coal to rivers for further shipment, and canals were beginning to be cut for moving goods between larger towns and cities.

During the Industrial Revolution, these different methods were improved and developed.

Navigable rivers

Rivers of Great Britain. All the major rivers were made navigable to a great or lesser degree. The Severn in particular was used for the movement of goods to the Midlands which had been imported into Bristol from abroad, and the export of goods from centres of production in Shropshire such as iron goods from Coalbrookdale. Transport was by way of Trows - small sailing vessels which could pass the various shallows and bridges in the river. These could navigate the Bristol Channel to the South Wales ports and Somerset ports, such as Bridgwater and even as far as France.

Roads

Much of the road system was bad, but some were turnpiked and maintained by a toll on the users. Major roads radiated from London and were the means by which the Royal Mail was able to reach the rest of the country. Heavy goods transport on these roads was by means of broad wheeled carts hauled by teams of horses. Lighter goods were conveyed by smaller carts or by teams of pack horses. Stage coaches transported people. The less wealthy walked.

Coastal sail

Sailing vessels were long used for moving goods round the coast. Transporting coal to London from Newcastle began in medieval times. The major seaports such as London, Bristol and Liverpool were the means by which raw materials such as cotton might be imported and finished goods exported. Transporting goods by sea was common during the whole of the Industrial Revolution and only fell away with the growth of the railways at the end of the period.

Railways

See main article History of rail transport in Great Britain

Wagonways for moving coal in the mining areas had started in the 17th century, and were often associatad with canal or river systems for the further movement of coal. These were all horse drawn or relied on gravity, with a stationary steam engine to haul the wagons back to the top of the incline. The first applications of the steam locomotive were on waggon or plate ways (as they were then often called from the cast iron plates used). Horse-drawn public railways did not begin until the early years of the 19th century. Steam-hauled public railways began with the Liverpool and Manchester and Stockton and Darlington Railways of the late 1820s. The construction of major railways connecting the larger cities and towns began in the 1830s but only gained momentum at the very end of the Industrial Revolution.

Canals

See main article History of the British canal system

Britain's canal network is, next to surviving mill buildings, the most enduring feature today of the Industrial Revolution. They tended to link the major manufacturing centres in the midlands with seaports and with London, at that time the largest manufacturing centre in the country. They were eventually largely killed off as commercial enterprises by the spread of the railways from the 1840s.

Social problems

The industrial revolution lead to a number of social problems within the newly developed working class. Children worked under miserable conditions and the families lived in bad housing.

Child labor

Child labor existed before the Industrial Revolution and in fact dates back to prehistoric times. But during the Industrial Revolution it grew more abusive than ever before. Politicians tried to limit child labor by law. Factory owners resisted -- they felt that they were aiding the poor by giving their children work from the age of five years onward. In 1833 the first law against child labor, the Factory Act of 1833, was passed in England: Children younger than nine were not allowed to work, they were not permitted to work at night and the work day of youth under the age of 18 was limited to twelve hours. Factory inspectors supervised the execution of this law. About ten years later children and women were forbidden to work in mining. These laws improved the situation; however child labor remained a problem in Europe up to the 20th century.

Luddites

The rapid industrialization of the English economy cost many craft workers their jobs. The textile industry in particular industrialized early, and many weavers found themselves suddenly unemployed since they could no longer compete with machines who only required relatively limit labor, unskilled labor as well, to produce more cloth than a single weever. Many such unemployed workers, weavers and others, turned their animousity towards the machines that had taken their jobs and began destroying factories and machinery. These attackers became known as Luddites, supposedly followers of Ned Ludd, a folklore figure. The first attacks of the Luddite movement began in 1811. The Luddites rapidly gained popularity, and the British government had to take drastic measures to protect industry.

The transatlantic industrial revolution

Effects

Roughly exponential increase in carbon dioxide emissions from fossil fuels, driven by increasing energy demands since the Industrial Revolution]]

The application of steam power to the industrial processes of printing supported a massive expansion of newspaper and popular book publishing, which reinforced rising literacy and demands for mass political participation. Universal white male suffrage was adopted in the United States, resulting in the election of the popular Andrew Jackson in 1828 and the creation of political parties organized for mass participation in elections. In the United Kingdom, the Reform Act 1832 addressed the concentration of population in districts with almost no representation in Parliament, expanding the electorate, leading to the founding of modern political parties and initiating a series of reforms which would continue into the 20th century. In France, the July Revolution widened the franchise and established a constitutional monarchy. Belgium established its independence from the Netherlands, as a constitutional monarchy, in 1830. Struggles for liberal reforms in Switzerland's various cantons in the 1830s had mixed results. A further series of attempts at political reform or revolution would sweep Europe in 1848, with mixed results, and initiated massive migration to North America, as well as parts of South America, South Africa, and Australia. The mass migration of rural families into urban areas saw the growth of bad living conditions in cities, long work hours without the traditional agricultural breaks (such as after harvest or in mid winter), a rise in child labour (the children received less pay and benefits than adults) and the rise of nationalism in most of Europe. The increase in coal usage saw a massive increase in atmospheric pollution.

The Industrial Revolution had significant impacts on the structure of society. Prior to its rise, the public and private spheres held strong overlaps; work was often conducted through the home, and thus was shared in many cases by both a wife and her husband. However, during this period the two began to separate, with work and home life considered quite distinct from one another. This shift made it necessary for one partner to maintain the home and care for children. Women, holding the distinction of being able to breastfeed, thus more often maintained the home, with men making up a sizeable fraction of the workforce. With much of the family income coming from men, then, their power in relation to women increased further, with the latter often dependent on men's income. This had enormous impacts on the defining of gender roles and was effectively the model for what was later termed the traditional family.

However, the need for a large workforce also pressured many women into industrial work, where they were often paid much less in relation to men. This was in large part due to a lack of organized labor among women to push for benefits and wage increases, and in part to ensure women's continued dependence on a man's income to survive.

Intellectual paradigms

Capitalist

The advent of The Enlightenment provided an intellectual framework which welcomed the practical application of the growing body of scientific knowledge — a factor evidenced in the systematic development of the steam engine, guided by scientific analysis, and the development of the political and sociological analyses, culminating in Adam Smith's The Wealth of Nations.

Criticism

The Second Industrial Revolution

The insatiable demand of the railroads for more durable rail led to the development of the means to cheaply mass-produce steel. Steel is often cited as the first of several new areas for industrial mass-production, which are said to characterize a "Second Industrial Revolution", beginning around 1850. This "second" Industrial Revolution gradually grew to include the chemical industries, petroleum refining and distribution, electrical industries, and, in the twentieth century, the automotive industries, and was marked by a transition of technological leadership from Great Britain to the United States and Germany.

The introduction of hydroelectric power generation in the AlpsBy the 1890s, industrialization in these areas had created the first giant industrial corporations with often nearly global international operations and interests, as companies like U.S. Steel, General Electric, and Bayer AG joined the railroads on the world's stock markets and among huge, bureaucratic organizations.

Industrial Revolution Themes

- Coal

- Coal mining

- Coke

- Cotton

- Industry

- Invention

- Iron

- Machinery, Manufacturing

- Metallurgy

- Sociology

- Steam power

- Steel

- Technology

- Textiles, Water power

- Workforce

People

- Richard Arkwright

- Thomas Boulsover

- Matthew Boulton

- James Brindley

- Isambard Kingdom Brunel

- Edmund Cartwright

- Henry Cort

- Thomas and George Cranege

- Samuel Crompton

- Abraham Darby I

- Abraham Darby II

- Abraham Darby III

- Francis Egerton, 3rd Duke of Bridgewater

- William Fairbairn

- James Hargreaves

- Thomas Highs

- Eaton Hodgkinson

- Benjamin Huntsman

- Joseph Marie Jacquard, Thomas Johnson (dressing frame), John Kay (flying shuttle)

- John Kay (spinning frame)

- Francis Cabot Lowell

- Lunar Society

- Thomas Newcomen

- Robert Owen

- Lewis Paul

- William Radcliffe

- Richard Roberts

- Thomas Savery

- John Smeaton

- George Stephenson

- Robert Stephenson

- Thomas Telford

- Richard Trevithick

- James Watt

- John Wilkinson

- John Wyatt

Places

- Abbeydale Industrial Hamlet

- Bridgewater Canal

- Broseley

- Coalbrookdale

- Cromford

- Derwent Valley Mills

- Ironbridge

- New Lanark

- Portsmouth Block Mills

- Quarry Bank Mill

- Soho Foundry

- Stockton and Darlington Railway

Invention technology

- Blast furnace

- Canal

- Cotton mill

- Crucible steel

- Dressing frame

- Factory

- Flying shuttle

- Newcomen steam engine

- Power loom

- Railway

- Reverberatory furnace

- Sheffield plate

- Spinning frame

- Spinning jenny

- Steam engine

- Stephenson's Rocket

- Water frame

- Watt steam engine

Social impact

- Bourgeoisie

- Child labour

- History of the Co-operative Movement

- Cottage industry

- Factory Acts

- Industrial unrest

- Luddite

- Proletariat

- Rochdale Pioneers

- Urbanization

- Industrial warfare

Reference

- History of technology

- History of the British canal system

- Industrial archaeology

- List of United Kingdom-related topics

- Timeline of clothing and textiles technology

- Timeline of invention

- Timeline of materials technology

- Timeline of steam power

See Also

Clip Art and Pictures

- Industrial Revolution Clipart, Pictures and Illustrations (http://classroomclipart.com/clipart/History/Industrial_Revolution.htm)