Wood router

|

|

Wood_router_jmc_2005_03_12.jpg

A router (pronounced rhowter was a woodworking tool used to rout out (hollow out) an area in the face of a piece of wood. It was a tool particularly used by pattern makers and consisted of a broad-based wooden plane with a narrow blade projecting well beyond its sole. Since about 1960, it has been replaced by the modern spindle router which was designed for the same work. Work to which the more recent plunging spindle router is even better adapted.

| Contents |

Moulding

The spindle router has also lent itself to the finer end of the scale of work done by a moulding spindle. That is it cuts grooves, edge moulding, and chamfers or it radiuses the edge of a piece of wood. It is also possible to use it for cutting some joints. The shape of cut that is created is determined by the size and shape of the bit (cutter) held in the collet and the depth by the depth adjustment of the sole plate.

Features of the modern spindle router

The tool usually consists of a vertically mounted electric motor with a collet on the end of its shaft. That drives the shank of the bit which projects to an adjustable extent through a flat sole plate (base). Control is derived from a handle on each side of the device.

There are two standard types of router - plunge and fixed. When using the machine as a router, a plunge router, sole is placed on the face of the work then the cutter is lowered into the work with the motor running. With a fixed router, the cut depth is set before the tool, together with the sole plate is lowered to the work with the motor running. In each case, the cutter cuts its way in but the plunging router does it in a more refined way.

The baseplate (sole plate) is circular and may be used in conjunction with a fence attached to the work or the work bench to obtain a straight cut. Without this, the varying reaction of the wood against the torque of the tool makes it impossible to control with the precision normally required.

As an alternative, the tool can be mounted below a router table and used as a miniature spindle. The machine is mounted below the bench in the manner of a circular saw bench and the work passed over it along a fence. It is sometimes possible to adjust the bench to give the effect of tilting a saw bench. That is to cut with the axis of the tool at an angle other than 90° to the face of the work.

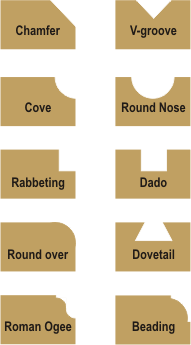

Available cutters

Router bits come in hundreds of varieties to create both decorative effects as well as joinery aids. They are classified as either high-speed steel (HSS) or carbide-tipped, and can be edge bits or non-edge bits. Edge bits have a small wheel bearing to act as a fence against the work in making edge mouldings. Non-edge bits require the use of a fence, either on a router table or attached to the work. Bits also differ by the diameter of their shank, with half-inch and quarter-inch shanks being the most common. Half-inch bits cost more but are more stable (giving smoother cuts) and are less likely to break. The shank and collet sizes must match. Many routers come with collets for both the popular shank sizes.

Most modern routers allow the speed of the bit's rotation to be varied. A slower rotation allows bits of larger diameter to be used safely. Typical speeds range from 10,000 to 24,000 rpm.

Variations on the theme

A tool similar to a router, but designed to hold smaller cutting bits - thereby making it easier to handle for small jobs - is a laminate trimmer. Another related tool, called a shaper or wood shaper, can be used for deeper or larger-diameter cuts. Some profile cutters use a cutting head reminiscent of a spindle router. These should not be confused with profile cuters for steel plate which use a flame.

Publicity blurb

The router was described as 'the most versatile tool in the world' by Jeremy Broun in his book "The Incredible Router". Hylton and Matlack also describe the router as a versatile tool (see Books below), "you can use it in just about every aspect of a job but assembly ... used creatively, it'll do almost any kind of cutting or shaping of wood." However, custom baseplates, templates, or jigs - tools that help guide the router or the workpiece through a controlled motion - are typically needed for more complex cuts.