Pressure gauge

|

|

| Contents |

Bourdon Tube Type

WPGaugeFace.jpg

WPPressGaugeMech.jpg

A pressure or vacuum gauge usually consists of a closed coiled tube (called a Bourdon tube) connected to the chamber or pipe in which pressure is to be sensed. As the pressure increases the tube will tend to uncoil, while a reduced pressure will cause the tube to coil more tightly. This motion is transferred through a link to a gear train connected to an indicating needle. The needle is presented in front of a card face inscribed with the pressure indications associated with particular needle deflections.

In the following pictures the transparent cover face has been removed and the mechanism removed from the case. This particular gauge is a combination vacuum and pressure gauge used for automotive diagnosis. The left side of the face, used for measuring manifold vacuum, is calibrated in centemeters of mercury vacuum on its inner scale and inches of mercury vacuum in its outer scale. The right portion of the face is used to measure fuel pump pressure and is calibrated in kilograms per square centemeter on its inner scale and pounds per square inch on its outer scale.

Mechanical details

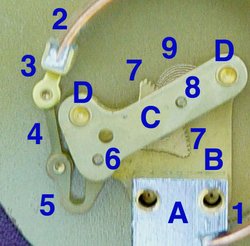

Stationary parts:

A: Receiver block. This joins the inlet pipe to the fixed end of the Bourdon tube (1) and secures the chassies plate (B). The two holes receive screws that secure the case.

B: Chassies Plate. The face card is attached to this. It contains bearing holes for the axles.

C: Secondary Chassis Plate. It supports the outer ends of the axles.

D: Posts to join and space the two chassis plates.

Moving Parts

1: Stationary end of Bourdon tube. This communicates with the inlet pipe through the receiver block.

2: Moving end of bourdon tube. This end is sealed.

3: Pivot and pivot pin.

4: Link joining pivot pin to lever (5) with pins to allow joint rotation.

5: Lever. This an extension of the sector gear (7).

6: Sector gear axle pin.

7: Sector gear.

8: Indicator needle axle. This has a spur gear that engages the sector gear (7) and extends through the face to drive the indicator needle. Due to the short distance between the lever arm link boss and the pivot pin and the difference between the effective radius of the sector gear and that of the spur gear, any motion of the bourden tube is greatly amplified. A small motion of the tube results in a large motion of the indicator needle.

9: Hair spring to preload the gear train to eliminate gear lash and hysteresis.

Aneroid Chamber (Bellows) Type

In gauges intended to sense small pressures or pressure differences, or require that an absolute pressure be measured, the gear train and needle may be driven by an enclosed and sealed bellows chamber, called an aneroid, which means "without liquid". (Early barometers used a column of liquid such as water or the liquid metal mercury suspended by a vacuum.) This bellows configuration is used in aneroid barometers (barometers with an indicating needle and dial card), altimeters, altitude recording barographs, and the altitude telemetry instruments used in weather balloon radiosondes. These devices use the sealed chamber as a reference pressure and are driven by the external pressure. Other sensitive aircraft instruments such as air speed indicators and rate of climb indicators (variometers) have connections both to the internal part of the aneroid chamber and to an external enclosing chamber.