Optical coating

|

|

Coating-1.jpg

Optically coated mirrors and lenses

An optical coating is a thin layer of material placed on an optical component such as a lens or mirror which alters the way in which the optic reflects and transmits light. One type of optical coating is an antireflection coating, which reduces unwanted reflections from surfaces, and is commonly used on spectacle and photographic lenses. Another type is the high-reflector coating which can be used to produce mirrors which reflect greater than 99% of the light which falls on them. More complex optical coatings exhibit high-reflection over some range of wavelengths, and anti-reflection over another range, allowing the production of dichroic thin-film optical filters.

Types of coating

The simplest optical coatings are thin polished layers of metals, such as aluminium, which are deposited on glass substrates to make mirror surfaces. The metal used determines the reflection characteristics of the mirror; aluminium is cheapest and most common coating, and yields a reflectivity of around 88%-92% over the visible wavelength range. More expensive is silver, which has a reflectivity of 95%-99% even into the far infrared, but suffers from decreasing reflectivity (<90%) in the blue and ultraviolet spectral regions. Most expensive is gold, which gives excellent (98%-99%) reflectivity throughout the infrared, but limited reflectivity below 550 nm wavelength, resulting in the typical gold colour.

By controlling the thickness and density of metal coatings, it is possible to decrease the reflectivity and increase the transmission of the surface, resulting in a half-silvered mirror.

The other major type of optical coating is the dielectric coating. These are thin layers of materials such as magnesium fluoride and calcium fluoride which are deposited onto the optical substrate. By careful choice of the exact composition, thickness, and number of these layers, it is possible to tailor the reflectivity and transmitivity of the coating to produce almost any desired characteristic. Reflection coefficients of surfaces can be reduced to less than 0.2%, producing an antireflection (AR) coating. Conversely, the reflectivity can be increase to greater than 99.99%, producing a high-reflector (HR) coating. The level of reflectivity can also be tuned to any particular value, for instance to produce a mirror that reflects 90% and transmits 10% of the light that falls on it; such mirrors are often used in lasers. Alternately, the coating can be designed such that the mirror reflects light only in a narrow band of wavelengths, producing an optical filter.

The versatility of dielectric coatings leads to their use in many scientific optical instruments (such as lasers, optical microscopes, refracting telescopes, and interferometers) as well as consumer devices such as binoculars, spectacles, and photographic lenses.

Antireflection coatings

Antireflection coatings are useful because of an particular property of optics. Whenever a ray of light moves from one medium to another (e.g., when light enters a sheet of glass after travelling through air), some portion of the light is reflected from the surface (known as the interface) between the two media. This can be observed when looking through a window, for instance, where a (weak) reflection from the front and back surfaces of the window glass can be seen. The strength of the reflection depends on the refractive indices of the two media as well as the angle of the surface to the beam of light. The exact value can be calculated using the Fresnel equations.

When the light meets the interface at normal incidence (i.e. perpendicularly to the surface), the amount of light reflected is given by the reflection coefficient or reflectance, R:

- <math>R = \left( \frac{n_0 - n_S}{n_0 + n_S} \right) ^2<math>,

where n0 and nS are the refractive indices of the first and second media, respectively. The value of R varies from 0.0 (no reflection) to 1.0 (all light reflected) and is usually quoted as a percentage. Complimentary to R is the transmission coefficient or transmitance, T. If the effects of absorption are neglected, then the value T is always 1-R. Thus if a beam of light with intensity I is incident on the surface, a beam of intensity RI is reflected, and a beam with intensity TI is transmitted into the medium.

Optical-coating-1.png

Reflection and transmission of an uncoated and coated surface

For a typical situation with visible light travelling from air (n0≈1.0) into common glass (nS≈1.5), value of R is 0.04, or 4%. Thus only 96% of the light (T=1-R=0.96) actually enters the glass, and the rest is reflected from the surface. The amount of light reflected is known as the reflection loss. (Note in a real situation with light travelling through a window, light is reflected both when going from air to glass and at the other side of the window when going from glass back to air. The size of the loss is the same in both cases. Light also may bounce from one surface to another multiple times, being partially reflected and partially transmitted each time it does so. In all, the combined reflection coefficient is given by 2R/(1+R). For glass in air, this is about 7.7%.)

The simplest form of antireflection coating was observed by Lord Rayleigh in 1886. He found that old, slightly tarnished pieces of glass transmitted more light than new, clean pieces. This effect can be explained by envisioning a thin layer of material with refractive index n1 between the air (index n0) and the glass (index nS). The light ray now reflects twice, once from the surface between air and the thin layer, and once from the layer-to-glass interface.

From the equation above, and the known refractive indices, reflectivities for both interfaces can be calculated, and denoted R01 and R1S, respectively. The transmission at each interface is therefore T01 = 1-R01 and T1S = 1-R1S. The total transmitance into the glass is thus T1ST01. Calculating this value for various values of n1, it can be found that at one particular value of optimum refractive index of the layer, the transmittance of both interfaces is equal, and this corresponds to the maximum total transmittance into the glass.

This optimum value is given by the geometric mean of the two surrounding indices, i.e.:

- <math>n_1 = \sqrt{n_0 n_S}<math>.

For the example of glass (nS≈1.5) in air (n0≈1.0), this optimum refractive index is n1≈1.225. The reflection loss of each interface is approximately 1.0% (with a combined loss of 2.0%), and an overall transmission T1ST01 of approximately 98%. Therefore an intermediate coating between the air and glass can reduce the reflection loss by half of its normal (uncoated) value.

The use of an intermediate layer to form an antireflection coating can be thought of as analoguous to the technique of impedance matching of electrical signals. (A similar method is used in fiber optic research where an index matching oil is sometimes used to temporarily defeat total internal reflection so that light may be coupled into or out of a fiber.) Further reduced reflection could in theory be made by extending the process to several layers of material, gradually blending the refractive index of each layer between the index of the air and the index of the substate.

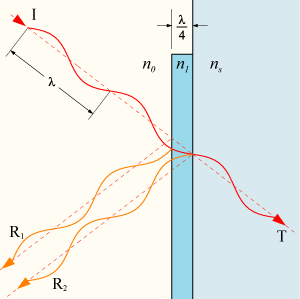

Practical antireflection coatings, however, rely on a intermediate layer not only for its direct reduction of reflection coefficient, but also use the interference effect of a thin layer. Assume the layer thickness is controlled precisely such that it is exactly one-quarter of the wavelength of the light deep (λ/4), forming a quarter-wave coating. If this is the case, the incident beam I, when reflected from the second interface will travel exactly half its own wavelength further than the beam reflected from the first surface. If the intensities of the two beams, R1 and R2, are exactly equal, then since they are exactly out of phase, they will destructively interfer and cancel each other. Therefore, there is no reflection from the surface, and all the energy of the beam must be in the transmitted ray, T.

Real coatings do not reach perfect performance, though they are capable of reducing a surface's reflection coefficient to less than 0.1%. Practical details include correct calculation of the layer thickness; since the wavelength of the light is reduced inside a medium, this thickness will be λ0 / 4n1, where λ0 is the vacuum wavelength. Also, the layer will be the ideal thickness for only one distinct wavelength of light. Other difficulties include finding suitable materials, since few useful substances have the required refractive index (n≈1.23) which will make both reflected rays exactly equal in intensity. Magnesium fluoride (MgF2) is often used, since this is hard-wearing and can be easily applied to substates using chemical vapor deposition, even though its index is higher than desirable (n=1.38).

Further reduction is possible by using multiple coating layers, designed such that relections from the surfaces undergo maximum destructive interference. One way to do this is to add a second quarter-wave thick higher-index layer between the low-index layer and the substrate. The reflection from all three interfaces produces destructive interference and antireflection. Other techniques use varying thicknesses of the coatings. By using two or more layers, each of a material chosen to give the best possible match of the desired refractive index and dispersion, broadband antireflection coatings which cover the visible range (400-700 nm) with maximum reflectivities of less than 0.5% are commonly achievable.

The exact nature of the coating determines the appearance of the coated optic; common AR coatings on eyeglasses and photographic lenses often look somewhat bluish (since they reflect slightly more blue light than other visible wavelengths), though green and pink tinged coatings are also used.

If the coated optic is used at non-normal incidence (i.e. with light rays not perpendicular to the surface), the antireflection capabilities are degraded somewhat. This occurs because a beam travelling through the layer at an angle "sees" a greater apparent thickness of the layer. The effect of this is that the anti-reflection band of the coating tends to move to longer wavelengths as the optic is tilted. Coatings can also be designed to work at a particular angle; beam splitter coatings are usually optimised for 45° angles. Non-normal incidence angles also usually cause the reflection to be polarization dependent.

High-reflection coatings

High-reflection (HR) coatings work the opposite way to antireflection coatings. Instead of a low refractive index layer, a material with a high index, such as zinc sulfide (n=2.32) or titanium dioxide (n=2.4) is used. This increased the reflection coefficient of the surface. By using several such layers, interspersed with low-index layers, a coating stack is built up which gives maximum reflectance. The thicknesses of the layers are generally quater-wave, this time designed such that reflected beams constructively interfere with one another to maximise reflection and minimise transmission. The best of these coatings can reach reflectivities greater than 99.999% (over a fairly narrow range of wavelengths). Common HR coatings can achieve 99.9% reflectivity over a broad wavelength range (hundreds of nanometres).

As for AR coatings, HR coatings are affected by the incidence angle of the light. When used away from normal incidence, the reflective range shifts to longer wavelengths, and becomes polarization dependent. This effect can be exploited to produce coatings that polarize a light beam.

By manipulating the exact thickness and composition of the layers in the reflective stack, the reflection characteristics can be tuned to a particular application, and may incorporate both high-reflective and anti-reflective wavelength regions. The coating can be designed as a long- or short-pass filter, a bandpass or notch filter, or a mirror with a specific reflectivity (useful in lasers). For example, the dichroic prism assembly used in some cameras requires two dielectic coatings, one long-wavelength pass filter reflecting light below 500 nm (to separate the blue component of the light), and one short-pass filter to reflect red light, above 600 nm wavelength. The remaining transmitted light is the green component.ru:Просветление оптики