Newcomen steam engine

|

|

Thomas Newcomen's atmospheric engine, today referred to as a Newcomen steam engine, was the first practical device to harness the power of steam to produce mechanical work. Newcomen engines were used throughout England and Europe to pump water out of mines starting in the early 18th century, and was the basis for James Watt's later improved versions. Although Watt is far more famous today (due largely to Matthew Boulton's tireless salesmanship), Newcomen rightly deserves the majority of the credit for the widespread introduction of steam power.

Prior to Newcomen a number of small steam engines of various sorts had been built, but most were essentially novelties. Around 1600 a number of experimenters used steam to power small fountains, first filling a container with water, then pressurizing it with steam to shoot it out. However these devices could not be scaled up, as the ability to produce large containers for high pressures simply didn't exist.

In 1662 Edward Somerset, second Marquis of Worcester, published a book containing several ideas he had been working on. One was a steam-powered fountain, which used vacuum instead of pressure. In his design two containers would alternately be filled with steam and then allowed to condense to produce a vacuum that would suck up more water from a well. A new charge of steam then pushed the water out as in earlier designs. By running the two containers back to back the fountain could be made somewhat continuous.

In 1698 Thomas Savery introduced a steam powered pump he called the Miner's Friend, essentially identical to Somerset's design and almost certainly a direct copy. Applied to pumping out mines, the water was no longer driven from the cylinder by a new steam charge, but simply allowed to flow out of a valve once the steam condensed and the cylinder was filled. The process of cooling and creating the vacuum was fairly slow, so Savery later added a small water inlet to quickly cool the steam.

Like other vacuum-based pumping systems, Savery's had the problem that it could not lift water more than 32 feet at a time. For deeper mines some sort of mechanical pump needed to be used, one that lifted the water directly instead of "sucking" it up. Such pumps were common already, but required a vertical recipocating action that Savery's system did not provide.

Several other experimenters attempted to provide mechanical work from existing engine designs. One of the most interesting was that of Denis Papin, who used a steam pump similar to Savery's and then ran the water over a water wheel. However a system that directly provided the work without the need for water would be a great improvement.

This problem was solved by Newcomen. He replaced the pipe leading to the mine with a piston inside the cylinder. Instead of pulling the water up as in Savery's engine, the piston would be pulled down by the vacuum instead. The piston was attached to a rocking beam to reverse the motion, thus pulling up instead of down, and from there to any sort of mechanical pump. In 1712, Newcomen and John Calley built their first engine on top of a water-filled mine shaft to demonstrate its power, pumping it out in hours. Soon orders from wet mines all over England were coming in. In 1711 his first commercial engine is completed, replacing a team of 500 horses. Since Savery's patent had not yet run out, Newcomen shared the patent due to his use of the water spray.

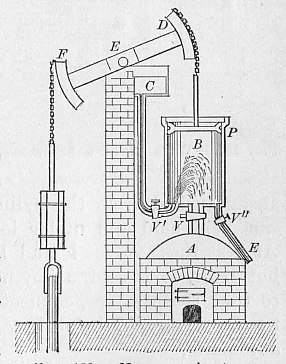

Newcomen's engine consisted of a boiler A, in which the steam was generated, and a cylinder B, in which a piston moved. When the valve V was opened, the steam was pulled into the cylinder by the piston P, which was attached to weights via the rocking arm at the top. At the top of the stroke, the valve V was closed, and valve V' was opened to allow cold water from the tank C into the cylinder, thus condensing the steam and reducing the pressure under the piston. The atmospheric pressure above then pushed the piston down again.

Early versions used manual operation of the valves to work, but the action was slow enough that this was not a serious concern. Later versions used controls attached to the rocking beam to open and close the valves automatically when the beam reached certain positions. The common story is that in 1713 a boy named Humphrey Potter, whose duty it was to open and shut the valves of an engine he attended, made the engine self-acting by causing the beam itself to open and close the valves by suitable cords and catches. This device was simplified in 1718 by Henry Beighton, who suspended from the beam a rod called the plugtree, which worked the valves by means of tappets.

By 1725 the engine was in common use in collieries, and it held its place without material change for about three-quarters of a century. Near the close of its career the atmospheric engine was much improved in its mechanical details by John Smeaton, who built many large engines of this type about the year 1770.

The main problem with the Newcomen design was that it was very expensive to operate. After the cylinder was cooled to create the vacuum, the cylinder walls were cold enough to condense some of the steam as it was sprayed in. This meant that a considerable amount of fuel was being used just to heat the cylinder back to the point where the steam would start to fill it again.

Newcomen's engine was only replaced when James Watt improved it to avoid this problem. In his design the cold water was held in a second container, attached to the steam cylinder via a pipe. When a valve on the pipe was opened, some of the steam would be cooled and create a small amount of vacuum, which in turn pulled in more of the steam, and so on. This eliminated the cooling of the main cylinder, and dramatically reduced fuel use. Watt's design, introduced in 1769, quickly replaced Newcomen's for new pumps, and was also retrofitted to most Newcomen installations already built. Watt licensed his design on the basis of the fuel it would save compared to a similar powered Newcomen.

A working replica of an early Newcomen Engine has been constructed at the Black Country Living Museum in Dudley.

See also

External Links

- Animated illustration (http://www.keveney.com/newcommen.html)pl:Silnik parowy Newcomena