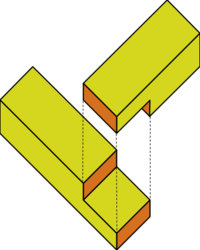

Lap joint

|

|

In woodworking, or metal fitting, a lap joint describes a technique for joining two pieces of wood by overlapping them. It is otherwise known as a halving joint. There are many types of lap joints.

- Half lap is used to describe the joining of wood end to end. It is a very crude form of scarf.

- Cross Lap is used for joints between mutually crossing pieces, usually cut at right angles.

- A dovetail lap joint forms a Tee-shaped joint which resists withdrawal of the stem from the cross-piece.

- A mitred halving joint shows a mitre on the face of the finished work.

Usually the wood is cut away to half its original thickness so that on joining, the original thickness is restored. With modern glues lap joints can be adequately strong and quite satisfactory although they may be regarded as very basic joints. Glue adhesion to the end grain is usually very poor so the weakness of a glued halving joint lies in the disposition of stress in the adjoining wood rather than to a failure of the joint itself. However, corner halving joints (called above, end lap joints), are inherently weak, especially when mitred.