Francis turbine

|

|

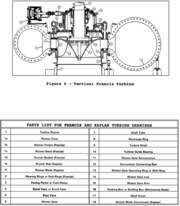

The Francis turbine was developed by James B. Francis. It is an inward flow reaction turbine that combines radial and axial flow concepts.

Francis turbines are the most common water turbine in use today. They operate in a head range of ten meters to several hundred meters and are primarily used for electrical power production.

| Contents |

Development

Water wheels have been used historically to powered mills of all types, but they are inefficient. 19th century efficiency improvements of water turbines allowed them to compete with steam engines (wherever water was available).

In 1826 Benoit Fourneyron developed a high efficiency (80%) outward flow water turbine. Water was directed tangentially through the turbine runner causing it to spin. Jean V. Poncelet designed an inward-flow turbine in about 1820 that used the same principles. S. B. Howd obtained a U.S. patent in 1838 for a similar design.

In 1848 James B. Francis improved on these designs to create a turbine with 90% efficiency. He applied scientific principles and testing methods to produce the most efficient turbine design ever. More importantly, his math and graphical calculation methods improved the state of the art of turbine design and engineering. His analytical methods allowed confident design of high efficiency turbines to exactly match a site's flow conditions.

Theory of operation

Francis_Turbine_High_flow.jpg

The Francis turbine is a reaction turbine, which means that the working fluid changes pressure as it moves through the turbine, giving up its energy. A casement is needed to contain the water flow.

The inlet is spiral shaped. Guide vanes direct the water tangentially to the runner. This radial flow acts on the runner vanes, causing the runner to spin. The guide vanes (or wicket gate) may be adjustable to allow efficient turbine operation for a range of water flow conditions.

As the water moves through the runner its spinning radius decreases, further acting on the runner. Imagine swinging a ball on a string around in a circle. If the string is pulled short, the ball spins faster. This property helps inward flow turbines harness water energy.

At the exit, water acts on cup shaped runner features, leaving with no swirl and very little kinetic or potential energy. The turbine's exit tube is specially shaped to help decelerate the water flow and recover kinetic energy.

Application

Francis_Turbine_inlet_scroll_Grand_Coulee_Dam.jpg

Large francis turbines are individually designed for each site to operate at the highest possible efficiency, typically over 90%. They are best suited for sites with high flows and low to medium head. Francis Turbines are very expensive to design, manufacture and install, but operate for decades.

In addition to electrical production, they may also be used for pumped storage; where a reservoir is filled by the turbine (acting as a pump) during low power demand, and then reversed and used to generate power during peak demand.

Francis turbines may be designed for a wide range of heads and flows. This, along with their high efficiency, has made them the most widely used turbine in the world.

Inexpensive francis microturbines (http://www.waterturbine.com/) are manufactured for individual power production with as little as ten feet of head.

See also

External links

- Turbine Introduction (http://www.du.edu/~jcalvert/tech/fluids/turbine.htm)

- GE Francis Turbines (http://www.gepower.com/prod_serv/products/hydro/en/turbines/francis.htm)

- Micro Hydro Turbine Manufacturer (http://www.waterturbine.com/)

- Voith Siemens (http://www.voithsiemenshydropower.com/vs_e_prfmc_pwrful_prdcts_turbines_francis.htm)