Disc brake

|

|

Disk_brake_dsc03682.jpg

The disc brake is a device for slowing or stopping the rotation of a wheel. A braking disc (or rotor in US English), usually of steel, is connected to the wheel or the axle. To stop the wheel, the braking pads (mounted in a device called a brake caliper) are squeezed mechanically or hydraulically against the disc on both sides. Friction causes the disc and attached wheel to slow or stop.

Cars, motorcycles, and some bicycles use disc brakes.

| Contents |

History

Experiments with disc-style brakes began in England in the 1890s; the first ever automobile disc brakes were patented by Frederick William Lanchester in his Birmingham factory in 1902, though it took another half century for his innovation to be widely adopted. The first designs resembling modern disc brakes began to appear in Britain in the late 1940s and early 1950s. They offered much greater stopping performance than comparable drum brakes, including much greater resistance to "brake fade" (caused by the overheating of brake components), and were unaffected by immersion (drum brakes were ineffective for some time after a water crossing, an important factor in off-road vehicles). Disc brakes are also more reliable than drum brakes due to the simplicity of their mechanics, the low number of parts compared to the drum brake, and ease of adjustment.

Disc brakes were most popular on sports cars when they were first introduced, since these vehicles are more demanding about brake performance. Many early implementations located the brake disc inboard, near the differential, but most discs today are located inside the wheels. (An inboard location reduces the unsprung weight and eliminates a source of heat transfer to the tires, important in Formula One racing.) Discs have now become standard in most passenger vehicles, though some retain the use of drum brakes on the rear wheels to keep costs and weight down as well as to simplify the provisions for a parking brake or emergency brake. As the front brakes perform most of the braking effort, this can be a reasonable compromise.

Mechanism

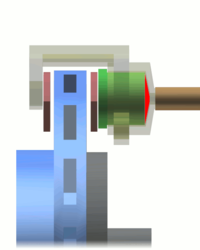

A single piston, floating caliper system.

Missing image

Missing image

Disc_brake_half_clamped.png

Inner shoe pushes against disc

Missing image

Disc_brake_clamped.png

Outer shoe is pulled toward disc

Pressurized brake fluid travels along the brake line to the caliper. The pressurized fluid pushes the piston (green) and inner brake pad against the disc (blue). Pressure against the disc pushes the caliper away from the piston, pulling the outer brake pad against the disc. As the brake pads clamp together, friction slows the rotation of the disc and wheel.

Discs

The design of the disc varies somewhat. Some are simply solid steel, but others are hollowed out with fins joining together the disc's two contact surfaces (usually included as part of a casting process). This "ventilated" disc design helps to dissipate the generated heat. Many motorcycle and sports car brakes instead have many small holes drilled through them for the same purpose. Additionally, the holes aid the pads in wiping water from the braking surface. Other designs include "slots" - shallow channels machined into the disc to aid in removing used brake material from the brake pads. Slotted discs are generally not used on road cars because they quickly wear down brake pads. However this removal of material is beneficial to race cars since it keeps the pads soft and avoids vitrification of their surfaces. Some discs are both drilled and slotted.

Disc damage modes

Discs are usually damaged in one of three ways: warping, scarring, and cracking. In addition, the useful life of the discs may be greatly reduced by excessive machining.

Warping

- Warping is caused by excessive heat build up, which softens the metal and can allow it to be disfigured. This can result in wheel shimmy during braking. The likelihood of warping can be reduced if the car is being driven down a long grade by several techniques. Use of a lower gear to obtain engine braking will reduce the brake loading. Also, operating the brakes intermittently - braking to a slower than cruising speed for a brief time then coasting will allow the brakes to cool between applications. The suitability of this is of course, dependent upon traffic conditions. Riding the brakes lightly will generate a great amount of heat with little braking effect and should be avoided. The wheel shimmy during braking is caused by thickness variation of the disc. Tests have shown that high temperature does not permanently warp discs.

Scarring

- Scarring can occur if brake pads are not changed promptly, all the friction material will wear away and the caliper will be pressed against the metal backing, reducing braking power and making scratches on the disc. If not excessive, this can be repaired by machining off a layer of the disc's surface. This can only be done a limited number of times as the disc has a minimum safe thickness. For this reason it is prudent to periodically inspect the brake pads for wear (this is done simply on a vehicle lift when the tires are rotated without disassembly of the components). When practical they should be replaced before the pad is completely worn.

Cracking

- Cracking is limited mostly to drilled discs, which get small cracks around the drilled holes. These cannot be repaired.

Unnecessary resurfacing machining

- Resurfacing machining has three purposes; to remove warps (restore planarity to the discs), to remove scoring, and to remove a glazed surface when new pads are installed. Brake shops will often resurface through a machining operation regardless of the need to do so due to warping or scarring. This can reduce the useful life of the disc in cases where only a light glaze removal (using emery cloth) would suffice. Reducing the life of the discs is of little concern to many brake shops as they can make money on replacing discs worn (or machined) below the manufacturer's minimum specified thickness.

Calipers

The brake caliper is the assembly which houses the brake pads and pistons. The pistons are usually made of aluminum or chrome plated iron. There are two types of calipers: floating or fixed. A fixed caliper does not move relative to the disc. It uses one or more pairs of pistons to clamp from each side of the disc, and is more complex and expensive than a floating caliper. A floating caliper (also called a "sliding caliper") moves with respect to the disc; a piston on one side of the disc pushes the inner brake pad till it makes contact with the braking surface, then pulls the caliper body with the outer brake pad so pressure is applied to both sides of the disc.

Floating caliper (single piston) designs are subject to failure due to sticking. This can occur due to dirt or corrosion if the vehicle is not operated. This can cause the pad attached to the caliper to rub on the disk when the brake is released. This can reduce fuel milage and cause excessive wear on the effected pad.

Pistons & cylinders

The most common caliper design uses a single hydraulically actuated piston within a cylinder, although high performance brakes use as many as 8. Modern cars use different hydraulic circuits to actuate the brakes on each set of wheels as a safety measure. The hydraulic design also helps multiply braking force.

Failure can occur due to failure of the piston to retract - this is usually a consequence of not operating the vehicle during a time that it is stored outdoors in adverse conditions. For high milage vehicles the piston seals may leak, which must be promptly corrected.

Brake pads

The brake pads are designed for high friction with the disc, while wearing evenly. The brake pads must be replaced regularly, and most are equipped with a method of alerting the driver when this needs to take place. Some have a thin piece of soft metal that causes the brakes to squeal when the pads are too thin, while others have a soft metal tab embedded in the pad material that closes an electric circuit and lights a warning light when the brake pad gets thin. More expensive cars may use an electronic sensor.

Early brake pads (and shoes) contained asbestos. When working on older car's brakes, care must be taken not to inhale any dust present in the caliper (or drum).

Parking brakes

Most vehicles include a mechanical parking brake system (also called an "emergency brake") which operates on the rear wheels. These systems are very effective with drum brakes, since these tend to lock. The adoption of rear-wheel disc brakes caused concern that a disc-based parking brake would not effectively hold a vehicle on an incline. Though some early vehicles (like the Toyota 2000GT) did use the disc for the parking brake, others used a tiny drum brake embedded inside the rear disc.

Today, most cars use the disc for parking, though some still rely on separate drums. The advent of electric parking brakes will change the rear caliper configuration substantially.

Materials advances

DSCN1379.JPG

Recently, carbon-ceramic and carbon-carbon composite brakes have been used in racing, sport car, and even high speed railroad train [1] (http://www.sglcarbon.com/sgl_t/brakedisc/products/train.html) applications. This should not be confused with ceramic brake pads for use with standard steel discs, which are simply high quality brake pads. Carbon-carbon brake discs are composed of carbon fiber within a carbon matrix, exploiting the excellent thermal conductivity of graphite. Among other things, they have been used in airplane brakes. Moisture can reduce the braking power of carbon-carbon brakes. Another major problem with carbon-carbon lies in its reactivity under high temperature. Additionally, carbon-carbon pads do not perform at their full capacity till they reach 300 °C. Above 500 °C the carbon will react with the air and burn, and even at normal braking temperatures there will be some burning of the outer layers. This is minimized by coating the disc, sometimes with carbon-ceramic.

Carbon-ceramic brake discs are composed of carbon fiber within a silicon carbide matrix (C/SiC). Carbon ceramic brakes are lightweight and have a very high specific heat and thermal conductivity, making them ideal as brake discs able to withstand over 1600 °C. They are also very expensive and require special pads, delegating them for use mostly on high end applications such as the Porsche Carrera GT. The lifespan of carbon-ceramic brakes is limited by cracking that occurs because of the different rates of expansion between the carbon and the silicon carbide. These cracks slowly allow air to come in contact with the carbon, resulting in burning.

The early Lotus Elise models came with Aluminium metal matrix composite (MMC) brake discs, these brakes were also lightweight and a cost effective alternative to the carbon/ceramic variations available but they cannot operate at the same temperatures. The manufacturer for these discs however closed down and Lotus was forced to switch to a iron disc once again; brakepads are however still available for the MMC discs.