Axial-flow compressor

|

|

The axial flow compressor is an improvement on the centrifugal compressor previously used in turbine engines,though small and micro turbines use centrifugal compressors with relative advantages (in terms of pressure ratios achieveable per stage of compression). The key improvement is that axial flow compressors work without radically changing the direction of gas flow.

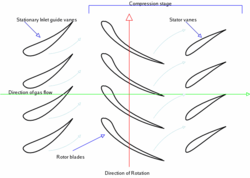

An axial flow compressor typically has a set of fixed inlet guide vanes to condition the incoming gas. There are then multiple compressor stages, each consisting of a set of rotating blades (much like a propeller) that force the gas to the rear, and then a set of fixed stator blades that condition the air ready for the next compressor stage.

The gas conditioning done by the stator blades is needed to ensure reasonable efficiency. Without the stator blades the gas would rotate with the rotor blades giving a big drop in efficiency.

Axial flow compressors are typically used in the compression stage of turbine engines. Their disadvantages (low increase in pressure at each stage) are outweighed by their advantages (multi-stages are very compact, they do continuous compression, and they are easy to drive).